Specifications :

A unique milling diagram

Patented*, LabMill’s innovative milling diagram is comprised of 5 consecutive steps:

• 2 breaking steps to make flour, fine middlings, coarse middlings, and bran.

• 1 sizing step to reduce coarse middlings to flour, fine middlings, and fine bran.

• 2 or 3 reduction steps to reduce fine middlings to flour.

Equipped with a precise scale, LabMill’s feed system releases a constant flow of grain, adapted to every type of wheat.

The grinding unit automatically switches from a first-breaking configuration to a second-breaking configuration. Reduction and converting are carried out on the same pair of smooth cylinders, a bypass selects the corresponding sieve. The cylinders are mounted on eccentric bearings, which allows for special adjustments.

A very precise feed system

Equipped with a precise scale, LabMill’s feed system releases a constant flow of grain, adapted to

every type of wheat.

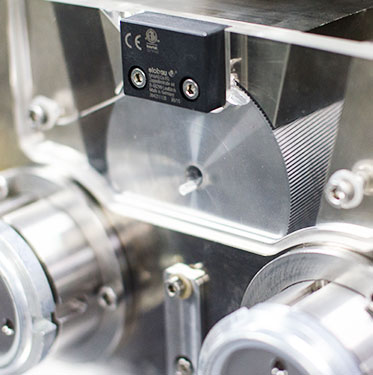

Adjustable cylinders

The grinding unit automatically switches from a first-breaking configuration to a second-breaking

configuration.

Reduction and converting are carried out on the same pair of smooth cylinders, a bypass selects the

corresponding sieve.

The cylinders are mounted on eccentric bearings, which allows for special adjustments.

A complete and compact mill

All access is via the top and front of the device, which allows you to carry out all analysis and

maintenance operations in optimal ergonomic conditions.

LabMill was developed within the Milling Quality Consortium (AFSA, Arvalis-institut du végétal,

ANMF, Danone Vitapole, INRA, IRTAC, Ulice, CHOPIN Technologies).

*Patent FR N° 0905572 | US N°9 067 210

LabMill is specifically designed to reach an industrial extraction

rate and make a representative flour quality.

High extraction rate

The extraction rate obtained on the LabMill is particularly high compared to its short

milling diagram.

It is between 66% and 81%, with an average of 77% for hard wheat and 75% for

soft wheat.

In comparison with a reference mill, more than 87% of extraction rates are correctly

predicted using the LabMill in a confidence interval of +/-1%.

This allows you to directly identify the lots of wheat most conducive to a high

extraction rate in industrial milling.

Excellent flour quality

LabMill is specifically designed to reproduce industrial milling conditions and to

obtain a representative flour quality.

Flour purity

Flour purity is traditionally measured by ash content. In LabMill’s case, it is

between 0.50% and 0.63%/ms, which corresponds to a 55 ash flour commonly

used in bread-making.

Technological quality

Flour purity, however, does not shed much light on its technological quality. A

comparison study between the results obtained on the Alveograph following

wheat milling under ISO 27971 demonstrates that the rheological quality of flour

made with LabMill is equivalent to flour made by industrial milling.

Numerous adaptation possibilities

LabMill is delivered preset and with a set of sieves allowing for use according to

the requirements of regulation ISO 27971. An experienced user, however, has the

possibility to create their own milling conditions by:

– Adjusting the gap of the grooved cylinders (Bk1 and Bk2)

– Adjusting the gap of the smooth cylinders (breaking and converting)

– Modifying the sifting time

– Changing feed speed of different products.

Catalogue : PDF

Reviews

There are no reviews yet.