Specifications :

Operating principle

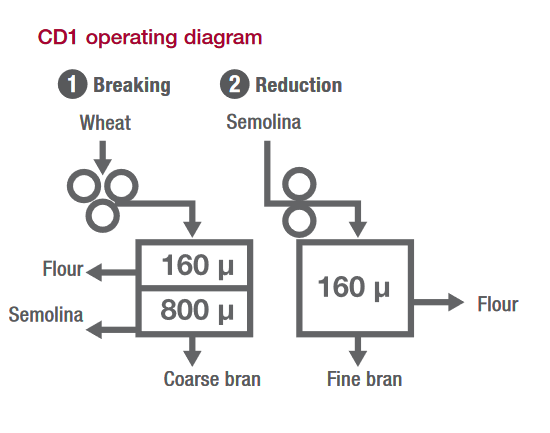

The CD1 Mill simulates the main steps in an industrial mill :

1/ Breaking with two streams between three fixed grooved cylinders.

2/ Centrifugal screening.

3/ Reduction by one or two streams between two smooth cylinders.

4/ Centrifugal screening.

CD1 operating diagram

The main applications

• Selecting wheat.

• Evaluating wheat mixes.

• Obtaining a representative flour for all your rheological analyses.

Catalogue : PDF

Reviews

There are no reviews yet.