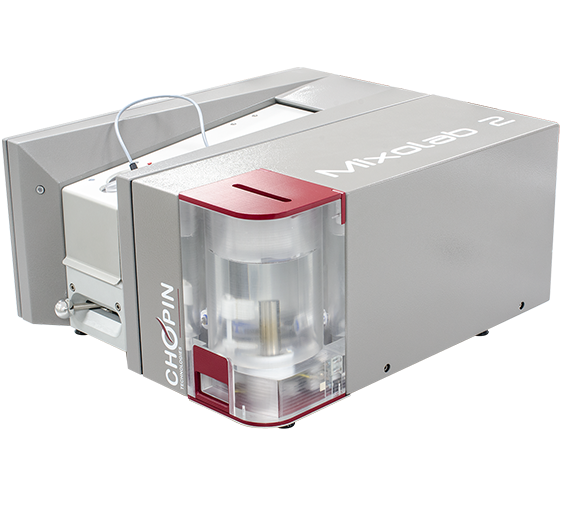

Specifications :

A reliable, innovative and efficient device

• Precise, automatic mixer temperature regulation (max: 90°C).

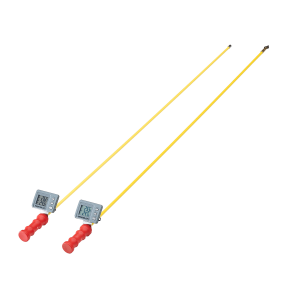

• Robust, easy to clean, dual component aluminium/stainless steel mixer.

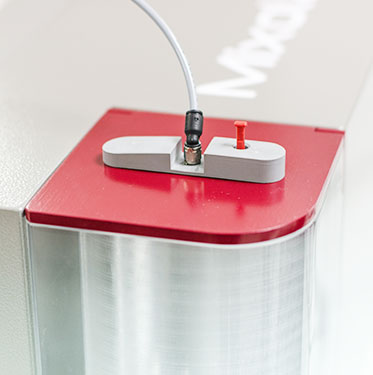

• Easy to remove water tank for simple, rapid cleaning.

• Water added automatically, rapidly and very precisely (+/- 0.02 ml). Possibility to add water

in different fractions (pump capacity: 75 ml).

• Full electronic calibration on all the measurement points on the Chopin+ curve (temperature

& torque) for greater analysis precision.

Simple, comprehensive and intuitive software – New

Temperature-specific stability index evaluating the dough’s resistance to temperature

increase (to supplement the conventional mixing stability value).

Possibility to carry out testing protocols varying both the temperature (max: 90°C) AND

the mixing speed (max 250 rpm), for example, to mimic a resting phase.

‘‘Blending law’’ function to create and save theoretical curves corresponding with prior

results.

‘‘Additive effect’’ function to directly visualize the optimum amount of additive to use.

Function creating automatic calculations at the end of the test, displaying the results of

‘‘predictive formulas’’, such as bread volume.

An integrated ‘‘Control chart’’ menu for monitoring the instrument’s precision.

An automatic C1 test to determine the flour’s hydration potential in less than eight minutes.

Results export in .csv or .xls file formats.

Integrated videos providing instructional tutorials.

Providing solutions

For Breeders

Facilitates wheat seed variety selection from generations F4-F5.

For Millers

• Wheat testing at point of delivery.

• Detection of pest-infestation in wheats.

• Wheat and flour blends optimization.

• Adaptation of flours for final uses through precise dosing of additives.

• Analysis of different flour mill streams.

• Assessing the impact of damaged starch.

For Bakers

• Verifying the conformity of delivered flours.

• Studying the rheological behavior of fiber-rich flours.

• Facilitates the elaboration of gluten-free products.

• Studying whole-wheat formulas.

For All

Optimization of customer specifications and quality control.

Application examples

• Analysis of wheat varieties (analysis of flours or ground grains).

• Analysis of various types of flour (bread wheat, durum wheat, barley, rye, rice, corn,

quinoa, cassava, etc.).

• Analysis of the effects of additives (enzymes, gluten, emulsifiers, protease, lipases,

cysteine, amylase) or ingredients (salts and substitutes, sugars, fats).

• Analysis of the effects of fibers on dough behavior.

• Evaluation of the effects of damaged starch.

• Analysis of dough sampled directly from the process line.

• And much more!

Advantages

Comprehensive

Comprehensive analysis of dough subjected to a cycle of warming and cooling.

Standardized

Compliant with ISO 17718, ICC173/1, AACC 54-60-01, NF V03-765, NFV03-764,

GOST 54498-2011 standards.

Simple

Automatic water addition; fully removable mixer for rapid cleaning.

Preventive maintenance messages displayed at regular intervals.

User friendly

PC controlled for complete traceability.

Software available in 12 languages.

Versatile

Works equally well with flours and ground cereal.

Customizable protocols.

Adaptable

Used in quality control and research and development.

Catalogue : PDF

Reviews

There are no reviews yet.