Specification:

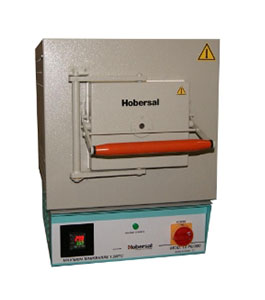

CHARACTERISTICS•Reinforced construction, metal case with chrome-phosphatizing base protection and external finish with heat-resistant metal paint. •Refractory parts engineered to resist extreme temperature changes, and specific ceramic paste types applied according to temperature and work fatigue of each part. •Heat resistance in refractory insulation of very low thermal conductivity coefficient. •Pantograph side door allows for a complete clear opening, protecting workers from ceramic block heat radiation. Pressure-adjusted door system, allowing for complete sealing. Half-opened door mode for a quick smoke evacuation. Electrically and thermally isolated door handle. BASIC ACCESSORIES •Extraction Chimney: Self-extraction design to eliminate smoke in processes that produce smoke in a considerable amount or when smoke extraction is advisable due to the nature of the process. Chimney outlet connection to a smoke bell or to the exterior by end user. •Forced air extraction chimney: Specially designed for a forced self-extraction to evacuate smoke fastat resistance in refractory insulation of very low thermal conductivity coefficient. •Bottom trays: Interchangeable, temperature uniform, with rim to protect against spilling, fusion or adherence of materials.

Reviews

There are no reviews yet.