Specifications :

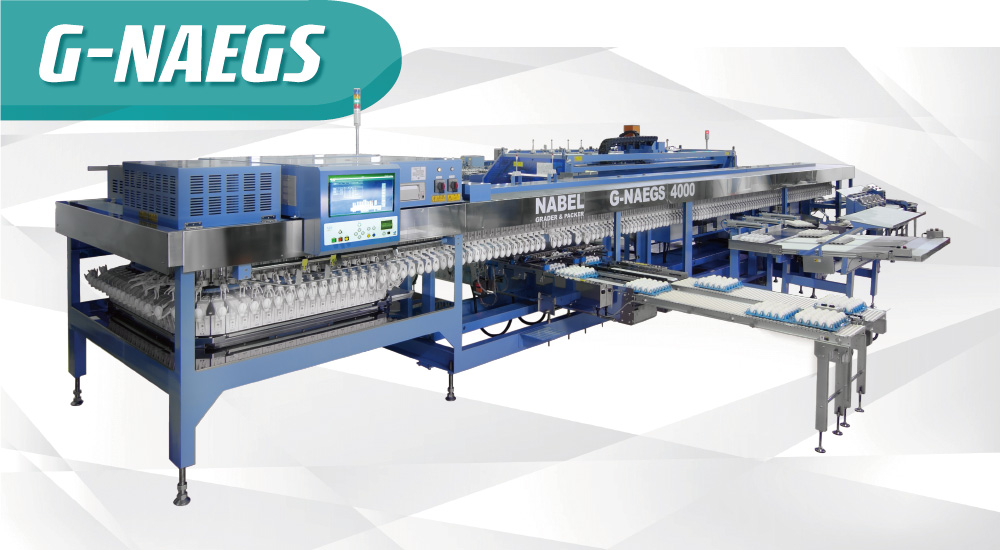

| Code | G-NAEGS4000 | G-NAEGS3500 | G-NAEGS3000 | |

|---|---|---|---|---|

| Capacity(Max.) | 40,000 eggs/hour | 35,000 eggs/hour | 30,000 eggs/hour | |

| Power required | Power capacity(Max.) | 3-phase 200V 75A*1 1-phase 100V 20A*2 |

||

| Air volume | 50~100L/min(ANR) | |||

| Hot water volume | 10L/min or over (60℃) | |||

| Water volume | 10L/min (200KPa)*3 | |||

| Container | Plastic pack | 5×2 3×2※4 4×2※4 6×2※4 | ||

| Pulp-mold tray | 5×8 5×9 6×9 6×5※4 | |||

| Plastic tray | 6×5 | |||

| Pulp-mold pack | 5×2 6×2※5 | |||

| Functions | Cassette type automatic feeder (4 sizes)*6 | |||

| Automatic feeder for pulp-mold trays (3 size) | ||||

| Automatic feeder for plastic 30-egg trays | ||||

| Automatic label feeding (4 sizes)*6 | ||||

| input and turnover printing | ||||

| Optional devices | Accumulator, Auto Loader, Chemical concentration adjuster, Multi-layer Egg Washer, Automatic Foamer, Automatic Dirt Detector, Automatic Crack Detector, UV Sterilizer, Abnormal Egg Detector, Feeder for specially designed packs, Carrier Washer, Fixed-weight packer program, Production indicator program*7, Repacking function*8 |

|---|

*1 Neccessary if all the above devices are used

*2 Fo product lines

*3 Neccessary if Automatic Foamer (optional) is used

*4 optional

*5 Compatible with carrier to exit robot system

*6 Installation up to five units

*7 Function for producing packs

*8 Packing function for eggs on traysDesigns and specifications are subject to change without notice.

*2 Fo product lines

*3 Neccessary if Automatic Foamer (optional) is used

*4 optional

*5 Compatible with carrier to exit robot system

*6 Installation up to five units

*7 Function for producing packs

*8 Packing function for eggs on traysDesigns and specifications are subject to change without notice.

NAEGS stands for NABEL Efficient Grading System.

It is a term coined by NABEL upon the separation of grading and packing for the first time in the world.

Catalogue : PDF

see more products in NABEL brand

Reviews

There are no reviews yet.